Kingspan K118 Kooltherm Insulated Plasterboards

Kingspan K118 Kooltherm Insulated Plasterboards

Price excludes VAT

Shipping calculated at checkout.Couldn't load pickup availability

**Minimum order value of £300 applies, excluding taxes**

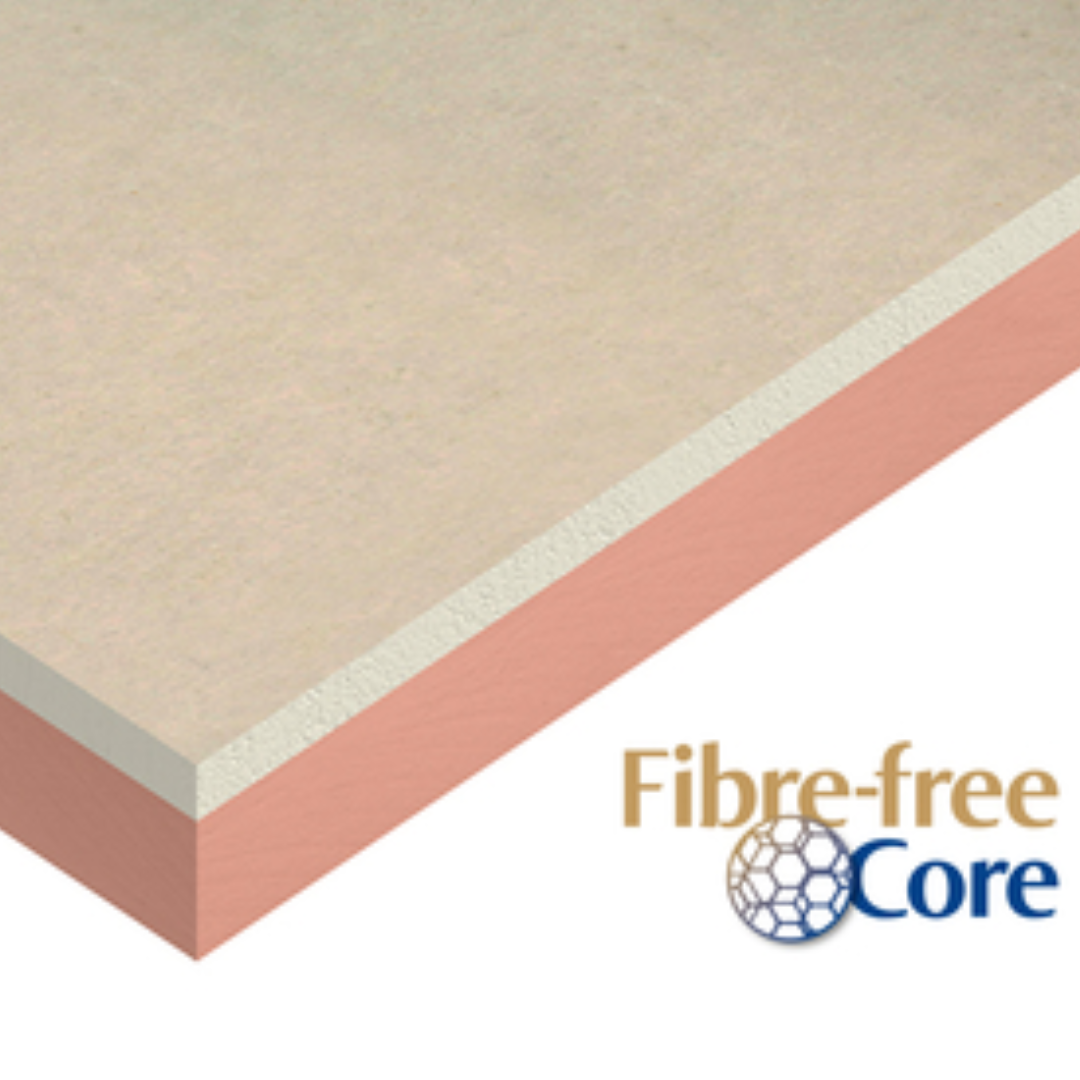

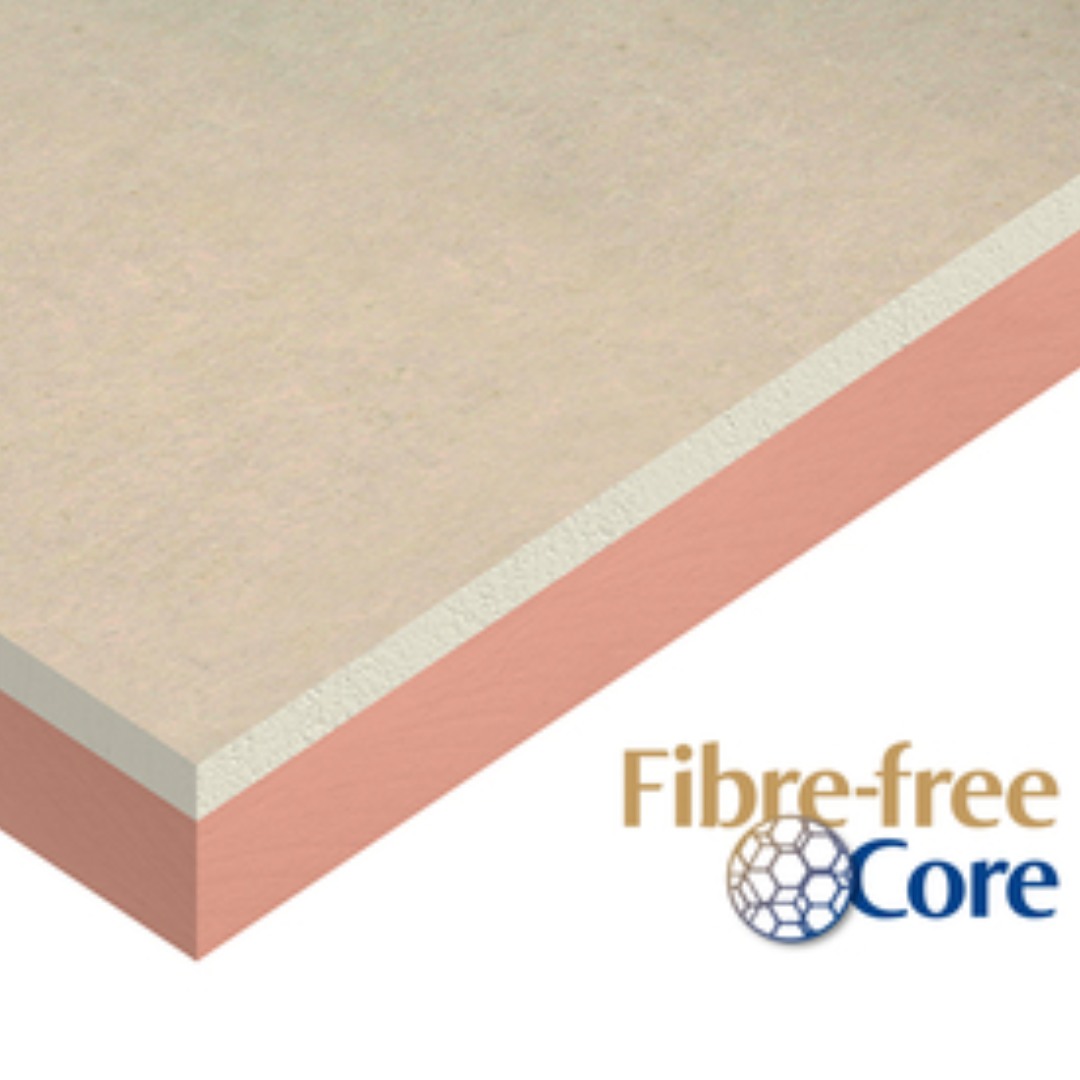

Kingspan Kooltherm K118 Insulated Plasterboard is a premium performance insulation with a fibre-free rigid thermoset phenolic core.

As part of our Kooltherm 100 range, it provides a top tier of performance for insulation materials with a thermal conductivity of just 0.019 W/mK across all thicknesses.

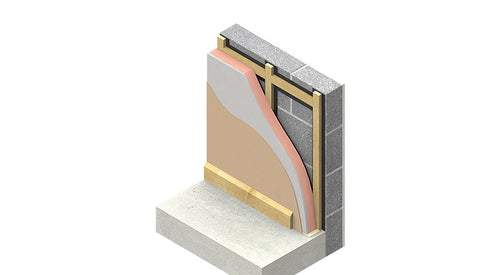

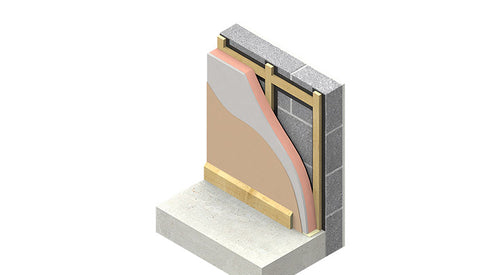

The product is an insulated plasterboard for mechanically fixed and adhesively bonded insulated dry-lining.

Kingspan K118 Board Sizes and Values

|

Kingspan K18 |

R Value (mK/W) |

Thermal Conductivity (W/mK) |

U-Value (W/m² K) |

Weight (kg per m² ) |

Compressive strength (kPa) |

Water vapaour resistance (MNs/g) |

Reaction to fire |

|

K118 32.5mm |

0.90 |

0.19/0.019 |

1.11 |

9.17 |

³ 125 |

> 100 |

Euroclass B-s1,d0 |

|

K118 37.5mm |

1.15 |

0.19/0.019 |

0.87 |

9.35 |

³ 125 |

> 100 |

Euroclass B-s1,d0 |

|

K118 42.5mm |

1.35 |

0.19/0.019 |

0.74 |

9.52 |

³ 125 |

> 100 |

Euroclass B-s1,d0 |

|

K118 52.5mm |

1.80 |

0.19/0.019 |

0.56 |

9.87 |

³ 125 |

> 100 |

Euroclass B-s1,d0 |

|

K118 62.5mm |

2.40 |

0.19/0.019 |

0.42 |

10.22 |

³ 125 |

> 100 |

Euroclass B-s1,d0 |

|

K118 72.5mm |

2.90 |

0.19/0.019 |

0.34 |

10.57 |

³ 125 |

> 100 |

Euroclass B-s1,d0 |

|

K118 82.5mm |

3.35 |

0.19/0.019 |

0.30 |

10.92 |

³ 125 |

> 100 |

Euroclass B-s1,d0 |

|

K118 92.5mm |

N/A |

0.19/0.019 |

N/A |

11.27 |

³ 125 |

> 100 |

Euroclass B-s1,d0 |

The Front Facings

The Reverse Face

The Core

CFC/HCFC–free

Compressive Strength

Water Vapour Resistance

Limitations

Durability

Resistance to Solvents, Fungi & Rodents

Fire Performance

Product Application

- Premium performance rigid phenolic insulation – thermal conductivity as low as 0.019 W/mK

- Class 0 / Low Risk fire rating

- Negligible smoke obscuration

- Insulation, dry–lining and vapour control in one board

- Little encroachment on room space

- Energy saving – allows quick response heating

- Resistant to the passage of water vapour

- Easy to handle and install

- Ideal for new build or refurbishment

- Non–deleterious material

- CFC/HCFC–free with zero Ozone Depletion Potential (ODP)

Fixing the Dry Lining Boards

Preparation

Window / Door Reveals and Soffits

Mechanical Fixing to Vertical Timber Framing / Battens

Mechanical Fixing to Metal Furring Systems

Mechanical Fixing to Timber Joists or Rafters

Mechanical Fixing Directly to Masonry Substrates

Finishing

Fire Stops

Installation Instructions

Cutting